Schematic diagram of the pilot-scale pulse-jet baghouse. A, pressure... | Download Scientific Diagram

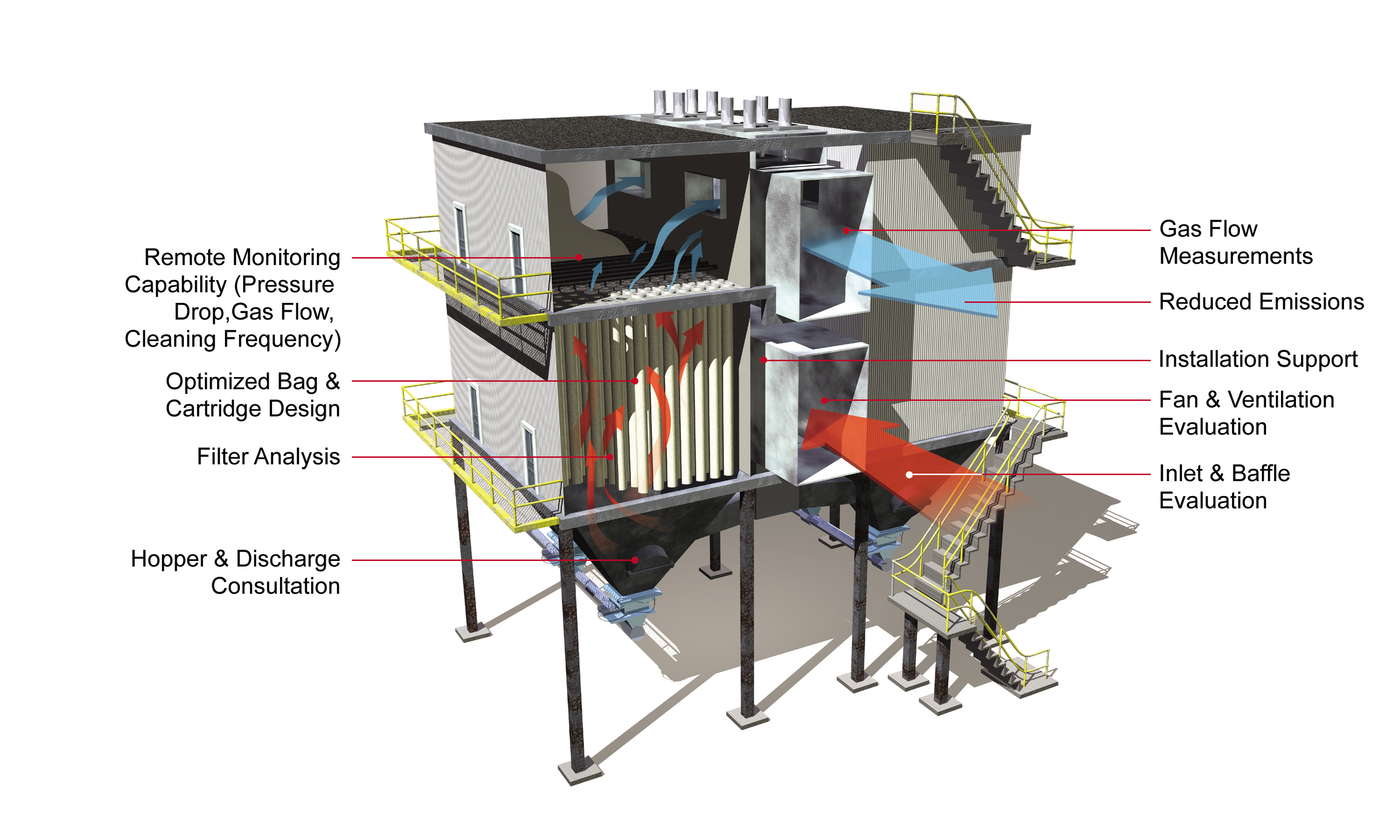

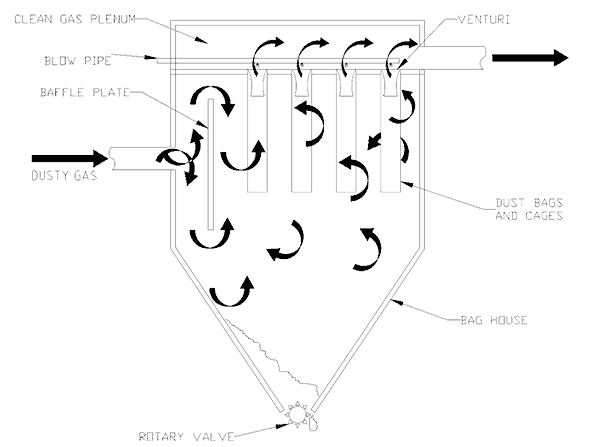

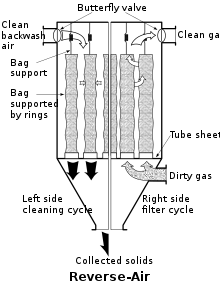

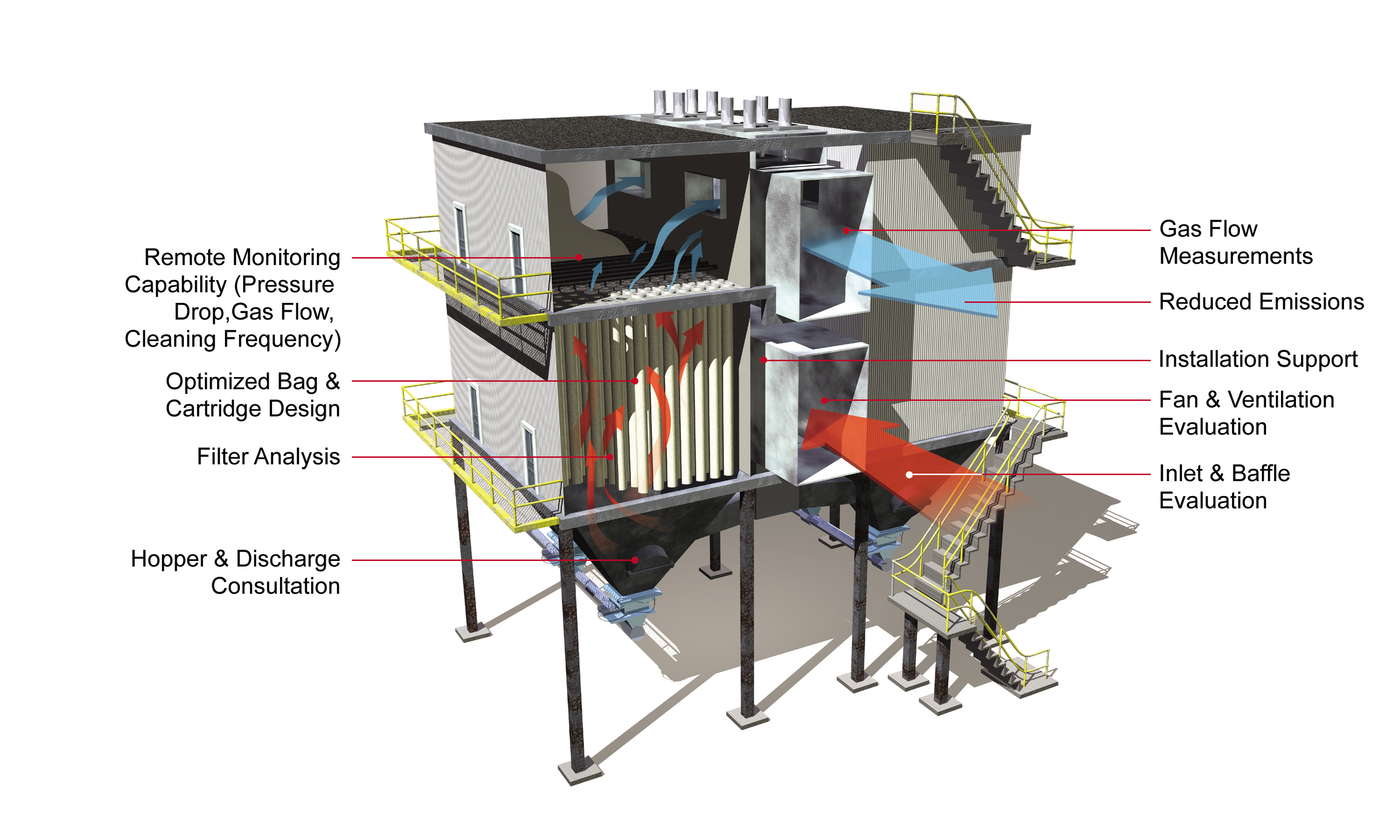

Schematic diagram of the pilot-scale pulse-jet baghouse. A, pressure... | Download Scientific DiagramContact Us Today! 800.334.7431 Silence iaccorp@iac-intl.com Our baghouse design process is superior to the line and ahead of the industry. Make the most of your dust collection system. Bringing innovative solutions to the air pollution control industry Baghouse DesignsM-Pulse BaghouseThe IAC M-Pulse Bag, a long bag, Medium pulse pressure bag is designed for efficient operation and effective cleaning for large gas flow applications. The M-Pulse is especially effective in coal, biomass and other applications for steam production. Modular design simplifies the application up to 2,000,000 CFM. Destination industry applications The main features of the product include Do you need a powder collector? and we will design, build and deliver your next baghouse. Pulse-Jet Modular Bag When it comes to high gas applications, do not look for our Pulse-Jet Baghouse Assembly Store anymore. 100% sold in store, this powder collector has many desired features. Due to its modular design, the structure is composed of separate modules. The benefit of a modular design is that a module can be cleaned separately out of line while others continue to work. Cleaning is completed by pulse injection which is the most efficient way to clean a filter bag. Its design and cleaning efficiency results in a useful 5-year bag life for the . Pulse Jet – Low to Medium Air Volume Pulse Jet CleaningIACs high pressure (70-100 PSI) Pulse Jet Baghouses have been tested for more than 20 years in thousands of facilities. The units can be used both to process gas and to nourish/recoil fuel dust. The filtering media from 44 ft2 to 21,818 ft2 are available in this design series. Snap- band type 6.25′′ bags in lengths of 36′′, 50′′′′, 72′′′, 96′′′, 120′′′ and 144′′′′ are pre-ingeniered in our standard design; however, the tube leaves can be easily configured for their own size bag for common parts. High-temperature Jet Filters These high-temperature pulse jet filter units use the state of low-density rigid art, high-porosity casting ceramic filter elements sometimes called "close filters". They are designed for the elimination of particle matter and other contaminants from industrial process gases in the most adverse conditions at temperatures of 1.650°F or 900°C. For severe acid gas applications, infused catalyst ceramic elements can be provided to comply with strict emission regulations. The highly active catalyst is formulated to be extremely effective in the simultaneous elimination of SOx, NOx, dioxins and particulate matter. These highly efficient and corrosion-resistant elements can work on systems up to 840 °F or 450 °C.Low Ratio Baghouse ANTE ESP conversions to Pulse Jet Cleaning If your capital budget has you in a bind, consider a conversion or stock reconstruction instead of a brand new collector. Baghouse dust collectors can be rebuilt or updated to a fraction of the cost of installing new collectors. Efficiency of collecting outdated designs of reverse air and agitation can also be improved with efficient cleaning of the pulse jet, usually increasing the amount of gas volume that the collector can clean without increasing the colector's size. The side walls, hoppers and ducts are reused in conversion, and a new "clean air fill" with bags and supplied. Savings are not only produced from reduced equipment. The reconstruction typically reduces demolition, support concrete, new electric wiring, crane time and work. A properly organized conversion can also minimize plant inactivity time in new systems. Bin Vent – High Pressure Press Jet Cleaning Ventilation FiltersFull IAC Bin Vent Filters in popular sizes, along with clean air plenums and tube sheets to accelerate the delivery of custom orders. The upper or side input units are available. Standard size Bin Vents range in size of single bag units to 480 Collector's bag that carry as much as 9,350 ft2 of cloth area. Inox applications (including feeding grade) are available, and IAC engineers can design a unit for their specific needs. Additional designs for dust collectorsPow pickers – High-pressure and vacuum designIAC designs and builds different styles and sizes of filter receptors based on the specific needs of the project and application requirements. IAC standard units carry up to 4,500 feet2 of cloth surface, and can select from lower load, side bag removal units, upper bag extraction units with Davit arms, walk plenums or removable upper doors. Filter receivers can be supplied with or without collection hoppers. (See drawings for details and dimensional options.) The links to drawings for standard units are listed below. Carbon steel, stainless steel (including feeding grade), and high strength/high pressure units are available. BAUMCO Baumco bags has been a basic product for reverse air collectors in electric ovens and casts for more than thirty years. When IAC purchased the Baumco product line, IAC inherited a design pool from Collectors of Fabric Filters, Coolers Evaporatives and Calor Air-Air Exchangers, along with designs of Collection ducts that can serve up to 2,000,000 CFM. While competitive with the M-Pulse IAC long bag, medium pulse pressure collector, IAC Baumco Reverse Air Baghouses can be the best choice of equipment in some applications, so IAC is pleased to keep them in our product line. IAC offers parts and service support for the Baumco Dust collector line and is pleased to offer pulse jet conversions to Baumco customers. Shaker IAC style cleaning filters build Baghouse dust collectors with a Shaker style bag cleaning mechanism in applications where compressed air is not available for cleaning filter bags or other conditions make it necessary. Cyclone and Multi-CloneIAC Mechanical Collectors of Cyclone use cyclonic action, centrifugal force to separate dust and particuled matter from the air current of the process. No fabric filter bags are required. Cyclones can be used as the primary collector or pre-Filter to a bag filter or other equipment. IAC Cyclone can be dimensioned and designed as required by the specific application and many configurations available. Multiclone collectors can be provided for a high CFM volume or greater efficiency. It also provides sparks and legs, as well as vortex rotor expansion hoppers and abrasion resistant inputs. Recent posts

For the full functionality of ResearchGate you need to enable JavaScript. Here's the .

Particulates: Media selection for pulse jet fabric filtration - Filtration + Separation

Pulse Jet Bag House Dust Collectors — Accendo Reliability

Pulse Jet Bag Filters: The Ultimate FAQ Guide | Filson Filter

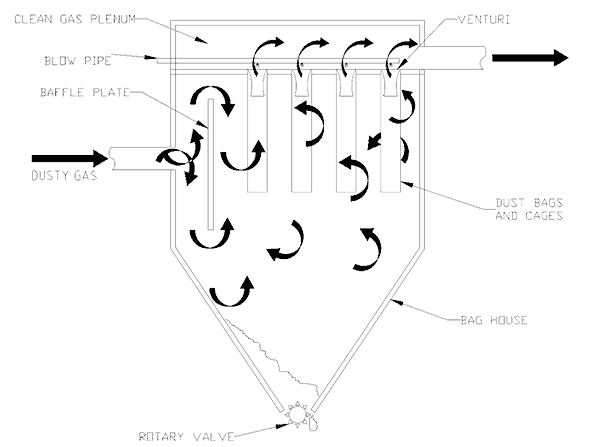

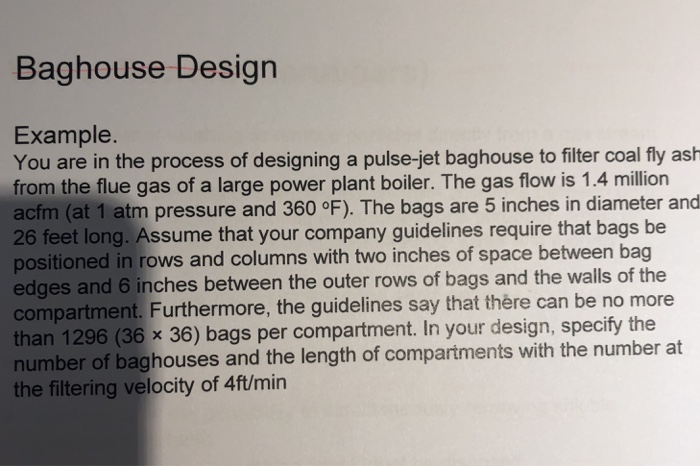

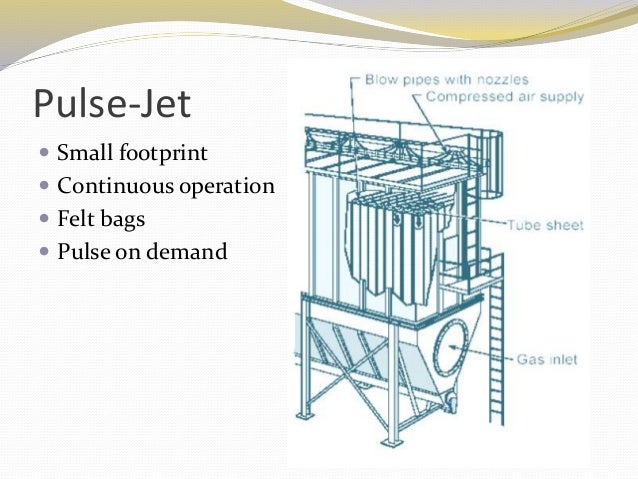

INDUSTRIAL POLLUTION: Pulse Jet

pulse jet bag filter, dust filter bag, filter bags, dust filter, filter cages, the problem of filter bag, maintenance of bag filter, why filter bag broken, why resistance increase in dust collector,

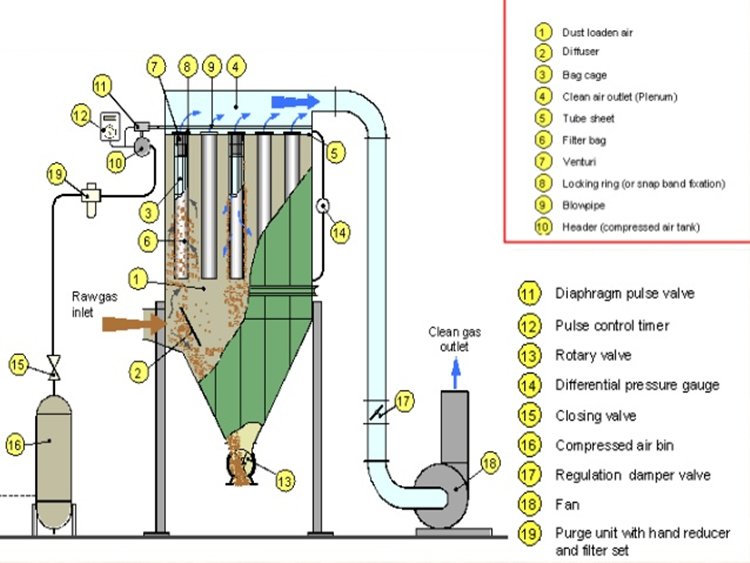

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

Pulse Jet Solenoid Valve - How They Work | Tameson

Pulse-Jet Bag Filter | Baghouse Dust Collector | Fabric Collector

Industrial pulse jet bag filter design /metal dust collector_Lifeierte Filter

Enviroflo Engineering - Enviroflo Engineering Pulse Jet Bag Filter

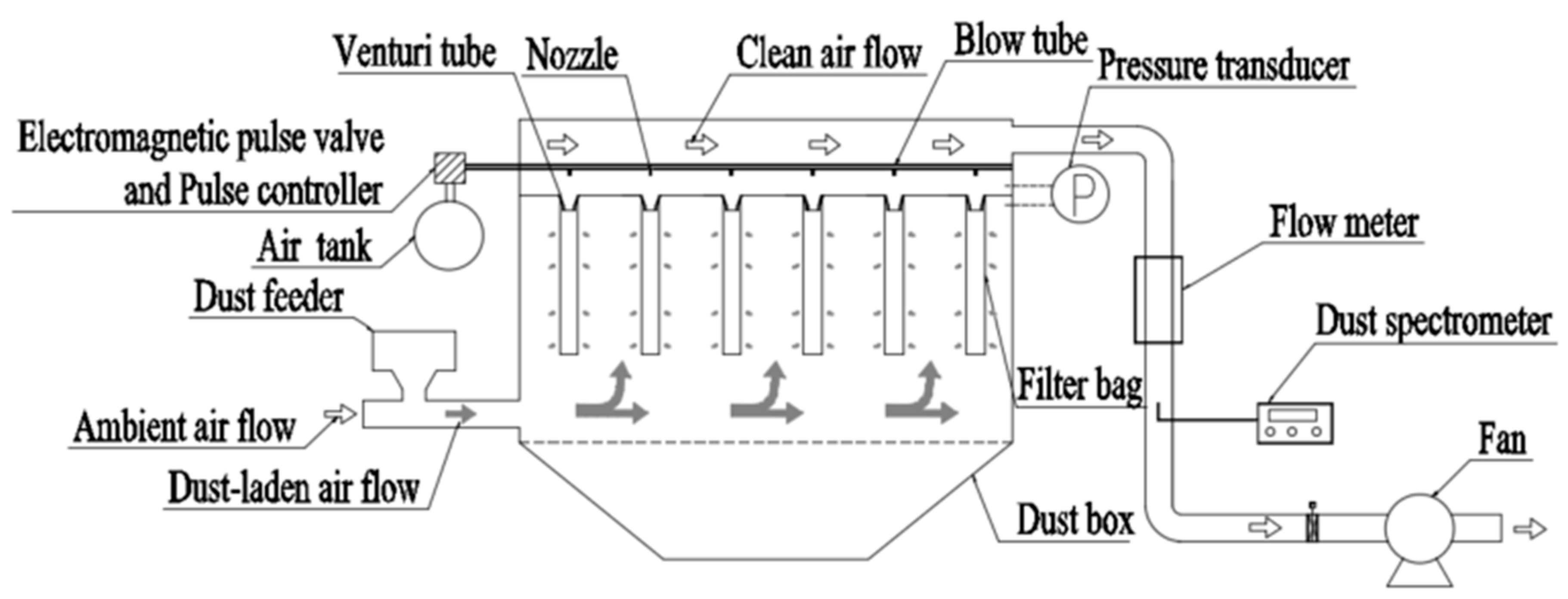

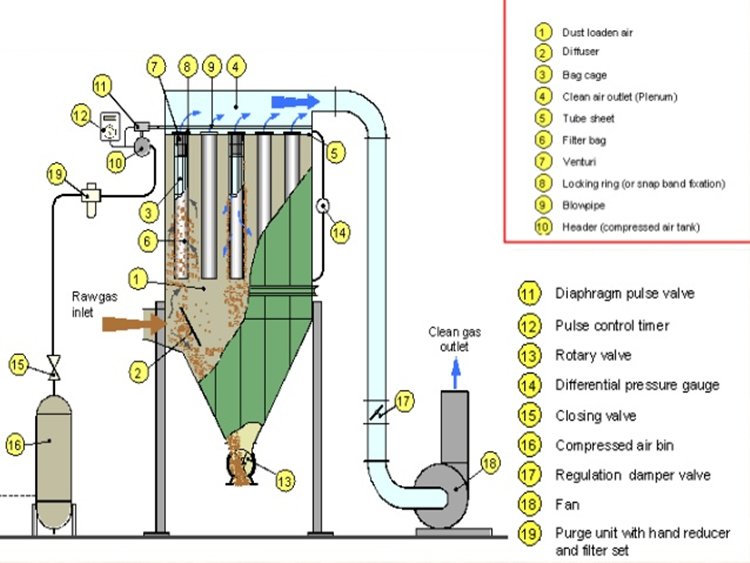

A schematic diagram of the pulse-jet bag filter test facility. | Download Scientific Diagram

Pulse jet bag filters | Filters, Pulses, Air conditioning system

Custom Designed Dust Collectors - Baghouses - GCE Systems

Getting the Dust Out: Selecting a Filtration System | powderbulksolids.com

Pulse-Jet Fabric Filter - an overview | ScienceDirect Topics

Pulse Jet Baghouse Industrial Dust Collection Systems | CAMCORP

Pulse Jet Bag Filters: The Ultimate FAQ Guide | Filson Filter

Pulse Jet Bag Filter Design - DesaignHandbags

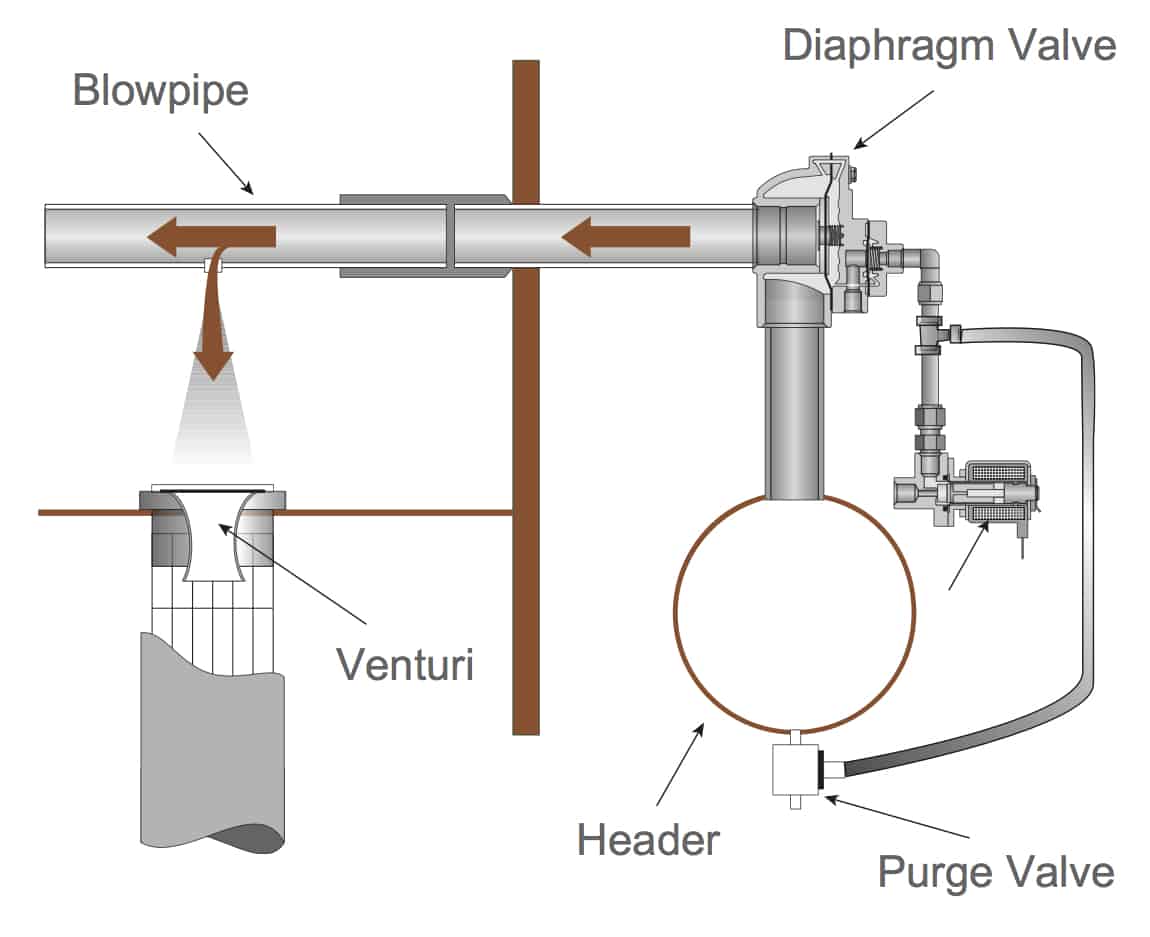

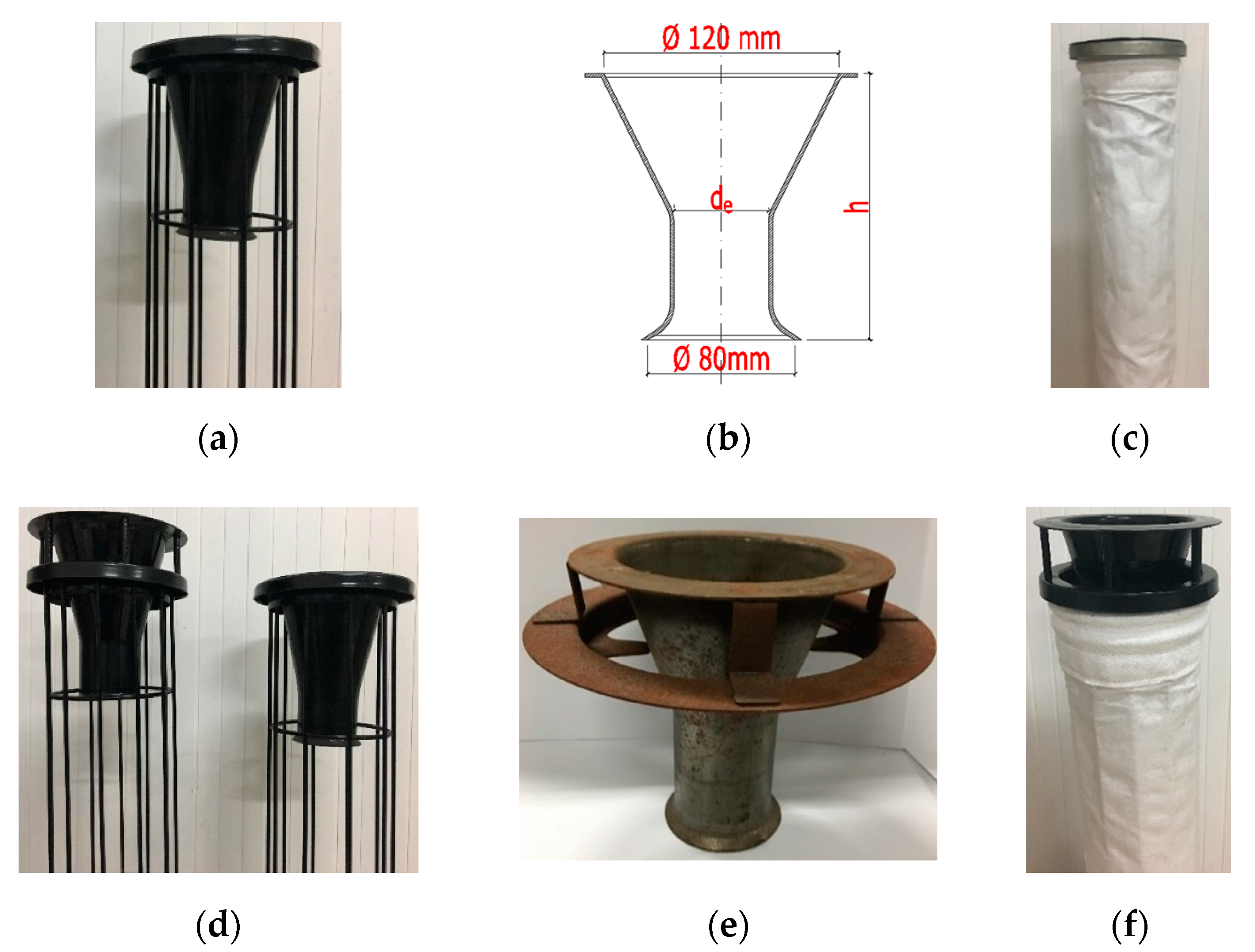

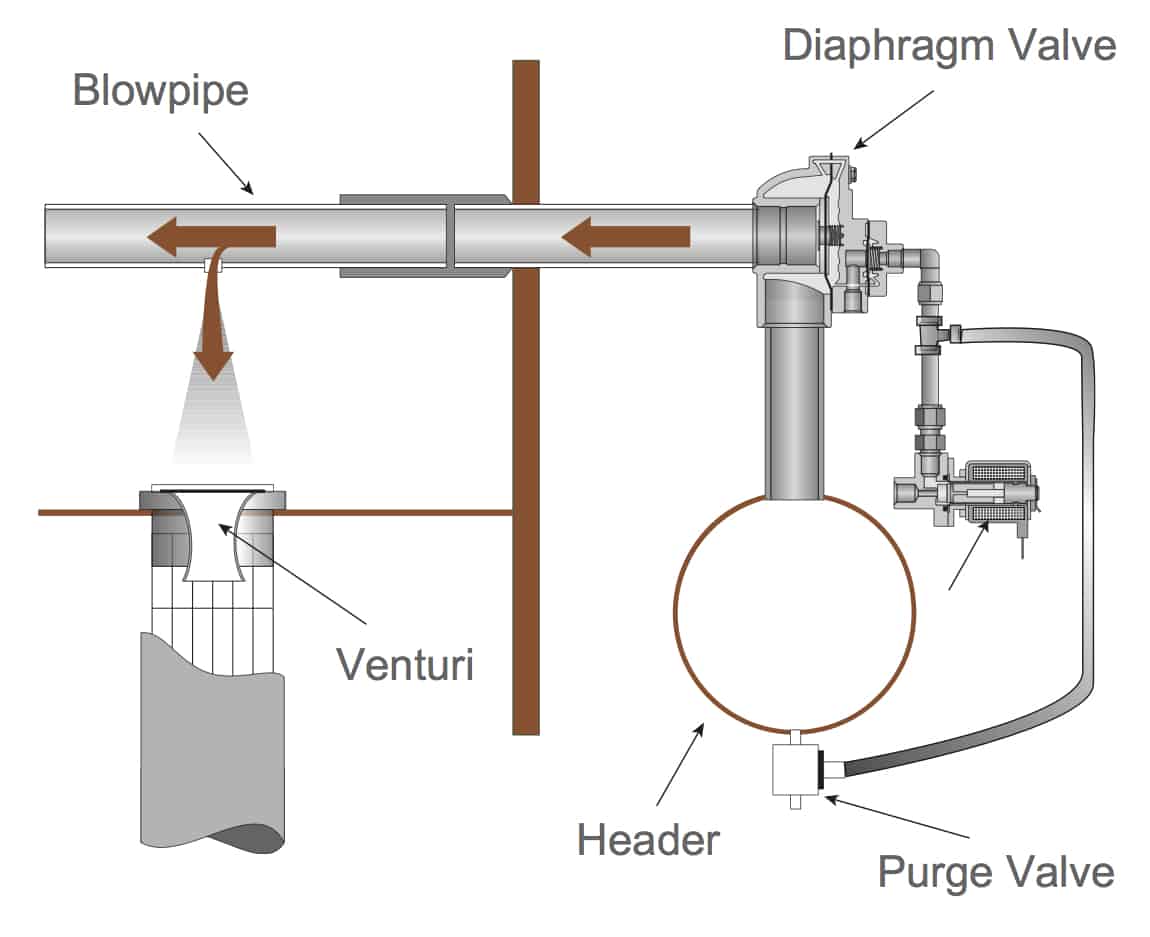

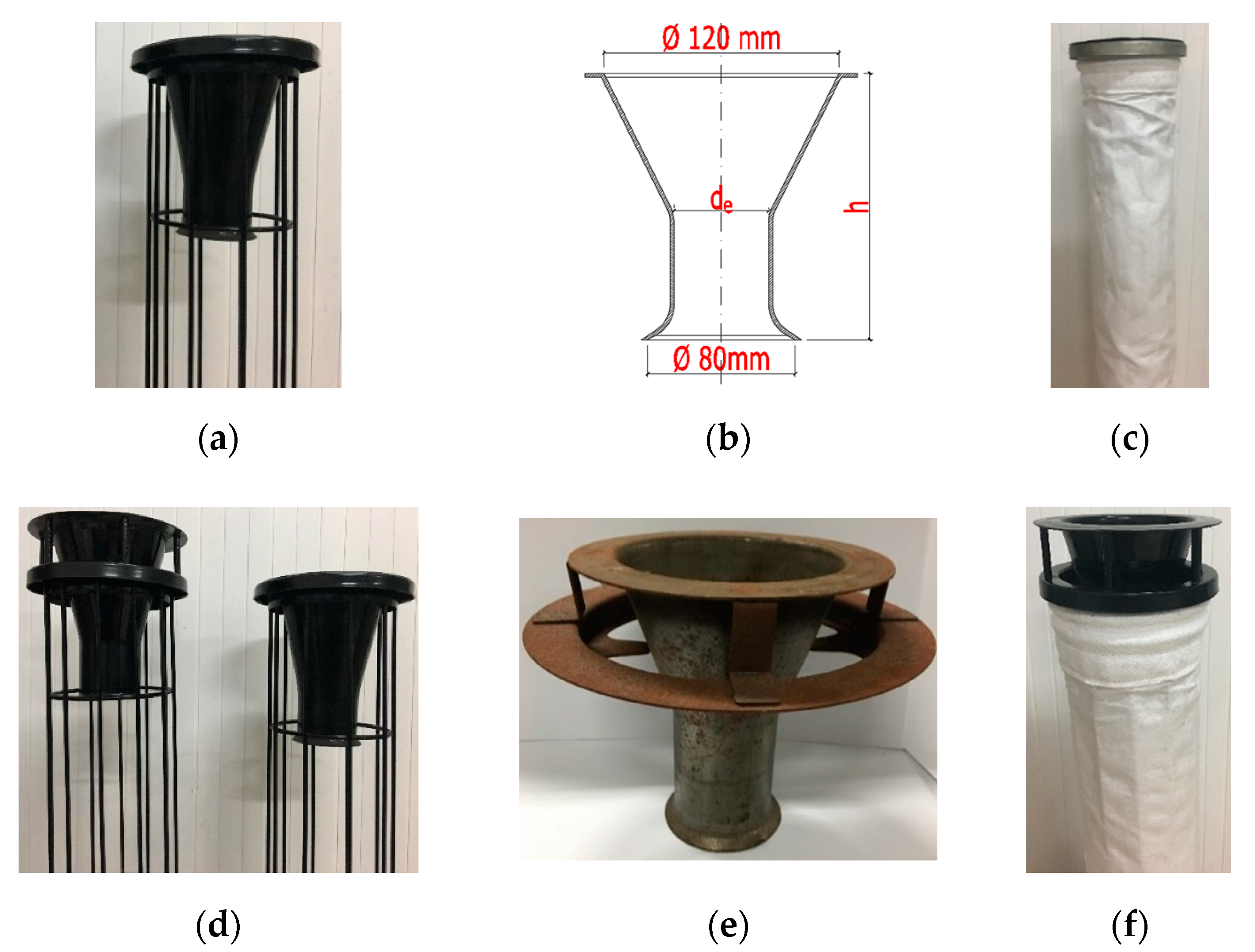

Applied Sciences | Free Full-Text | Effect of Venturi Structures on the Cleaning Performance of a Pulse Jet Baghouse | HTML

Making Sense of Dust Collection Technology | powderbulksolids.com

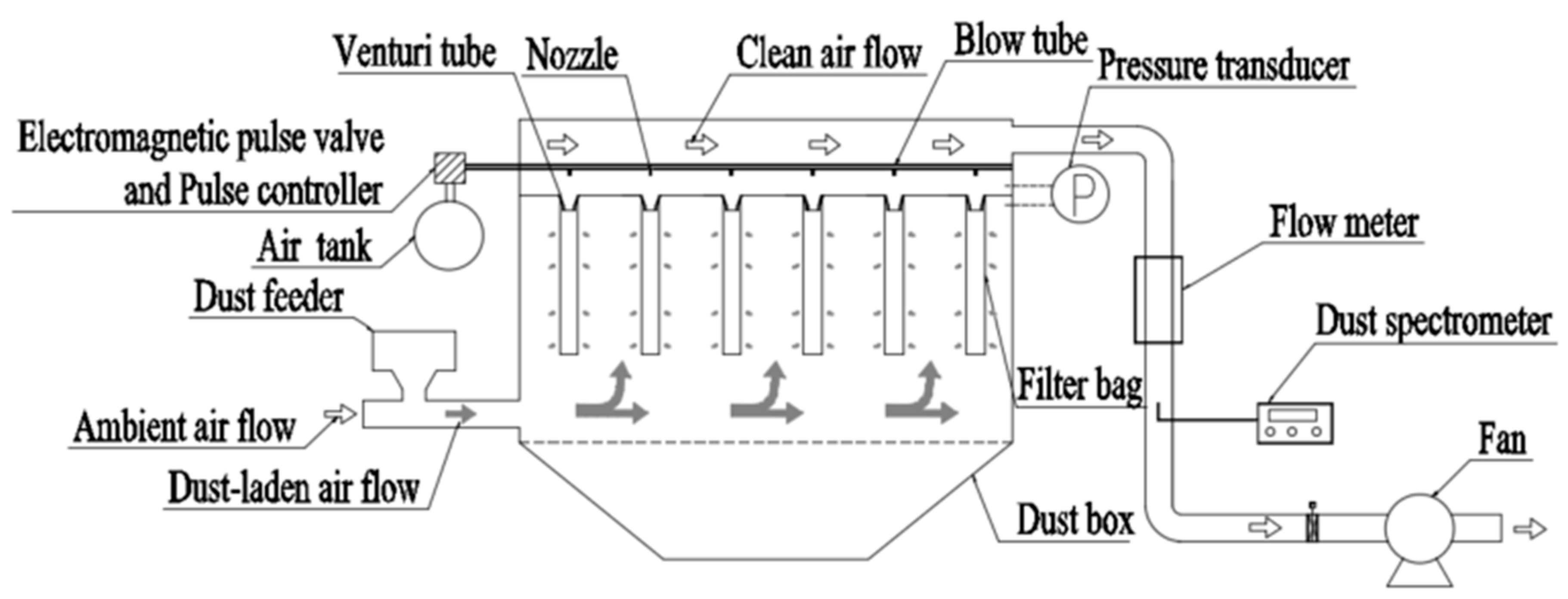

PDF) A Pilot-Scale Study of the Design and Operation Parameters of a Pulse-Jet Baghouse

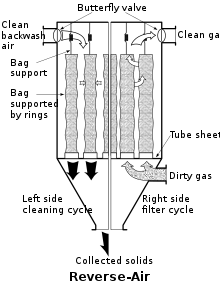

Baghouse - Wikipedia

Neundorfer | Optimizing the Performance of Air Pollution Control Equipment

Numerical and experimental study of pulse-jet cleaning in fabric filters - ScienceDirect

Custom Designed Dust Collectors - Baghouses - GCE Systems

Bag Filter Pulse Jet Design - DesaignHandbags

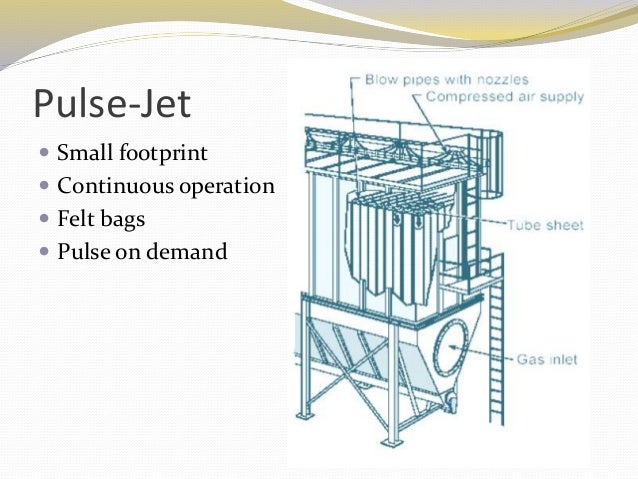

BAGHOUSE 101 TRAINING Presented by: March 10, ppt download

Fabric Filter Bag and Baghouse Specifications

GORE® Industrial Baghouse Filters: Membrane Construction | Gore

China Jdmc148X2 Pulse Jet Bag House Dust Collector Solution for Food Workshop. - China Fabric Filter, Dust Collector

Baghouse Dust Collection | LDX Solutions | Fabric Filter Dust Collector

Pulse Jet Bag Filter | Baghouse dust collector | Apzem, India.

Applied Sciences | Free Full-Text | Effect of Venturi Structures on the Cleaning Performance of a Pulse Jet Baghouse | HTML

Not all Pulsejet Filters are Created Equal | Airtight Solutions

Pulse-Jet Fabric Filter - an overview | ScienceDirect Topics

Air blow pipe design for bag filter house, Dust bag filter house, dust collector, dust filter bag house, pulse jet bag filter housing, clean system of bag house, problem of dust collector,

Neundorfer | Optimizing the Performance of Air Pollution Control Equipment

Pulse Jet Fabric Filter - DesaignHandbags

Pulse Jet Baghouses

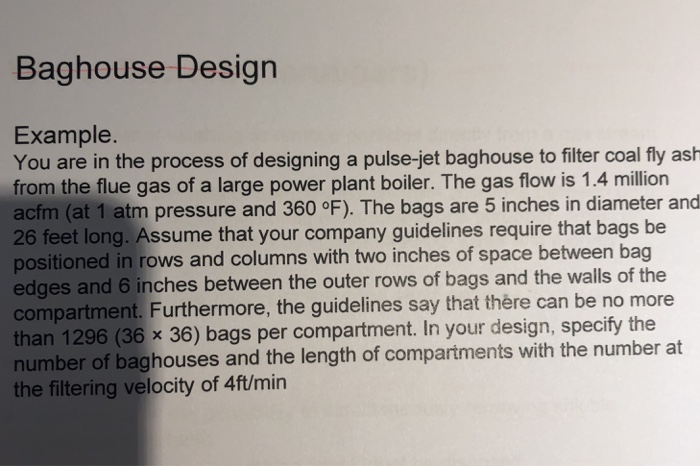

Solved: Baghouse Design Example You Are In The Process Of ... | Chegg.com

Schematic diagram of the pilot-scale pulse-jet baghouse. A, pressure... | Download Scientific Diagram

Schematic diagram of the pilot-scale pulse-jet baghouse. A, pressure... | Download Scientific Diagram

Posting Komentar untuk "pulse jet baghouse design"